Robots have revolutionized operations across various sectors, from manufacturing assembly lines to hospital corridors, creating unprecedented efficiency and precision. As technology advances, their applications continue to expand, transforming how we work, live, and interact with machines across multiple industries.

Key Takeaways

- The global industrial robotics market is projected to grow from $55.1 billion in 2025 to $291.1 billion by 2035, with manufacturing leading adoption.

- Healthcare robots are reducing infection rates through UV-C disinfection technology while pharmacy automation grows rapidly.

- Agricultural robots can reduce pesticide use by up to 20% through precision spraying techniques.

- Warehouse automation improves inventory accuracy from 63% to 89% in automated facilities.

- Educational robots are creating a market projected to reach $5.84 billion by 2030, transforming STEM education.

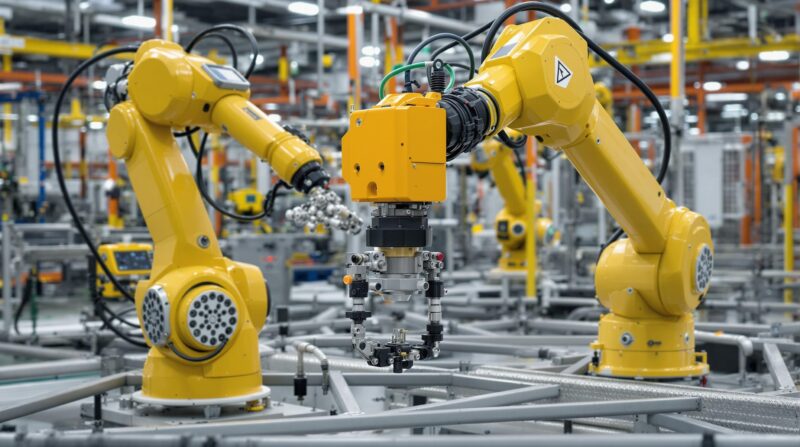

Manufacturing: The Industrial Backbone of Robotics

Manufacturing represents the most established sector for 10 uses of robots, with a record 4 million industrial robots operational globally in 2023. China leads installations with 276,288 units, representing 51% of the global total. Collaborative robots (cobots) work alongside humans, handling repetitive tasks while workers focus on complex operations requiring judgment.

The financial outlook is impressive, with the market projected to grow from $55.1 billion in 2025 to $291.1 billion by 2035, fueled by an 18.1% CAGR. This growth highlights how deeply integrated robots have become in production environments. While China’s domestic manufacturers capture 47% of its market, Japan saw a 9% decline in installations, showing regional differences in adoption strategies.

AI-driven predictive maintenance has transformed how factories operate, with robots self-diagnosing potential failures before they occur, dramatically reducing expensive downtime. The International Federation of Robotics reports these advances are cutting labor costs while simultaneously improving product quality and consistency.

Warehousing & Logistics: Transforming Supply Chains

Warehousing and logistics represent areas where robots are used extensively, creating more efficient supply chains through automation. The warehouse robotics market is expanding rapidly from $6 billion in 2022 to a projected $15.7 billion by 2030. This growth is driven by e-commerce demands, with over 100,000 mobile robots shipped in 2021 alone.

Robots in this sector primarily handle three key applications:

- Palletizing (28% of applications)

- Sorting (22% of applications)

- Transportation (15% of applications)

These automated systems have reduced operational costs by 30% in 2023 while significantly improving inventory accuracy from 63% to 89% in automated facilities. Automated guided vehicles (AGVs) navigate warehouse floors independently, transporting items between stations without human intervention. RFID tracking integrated with robotics ensures near-perfect inventory counts, addressing a major pain point for distribution centers.

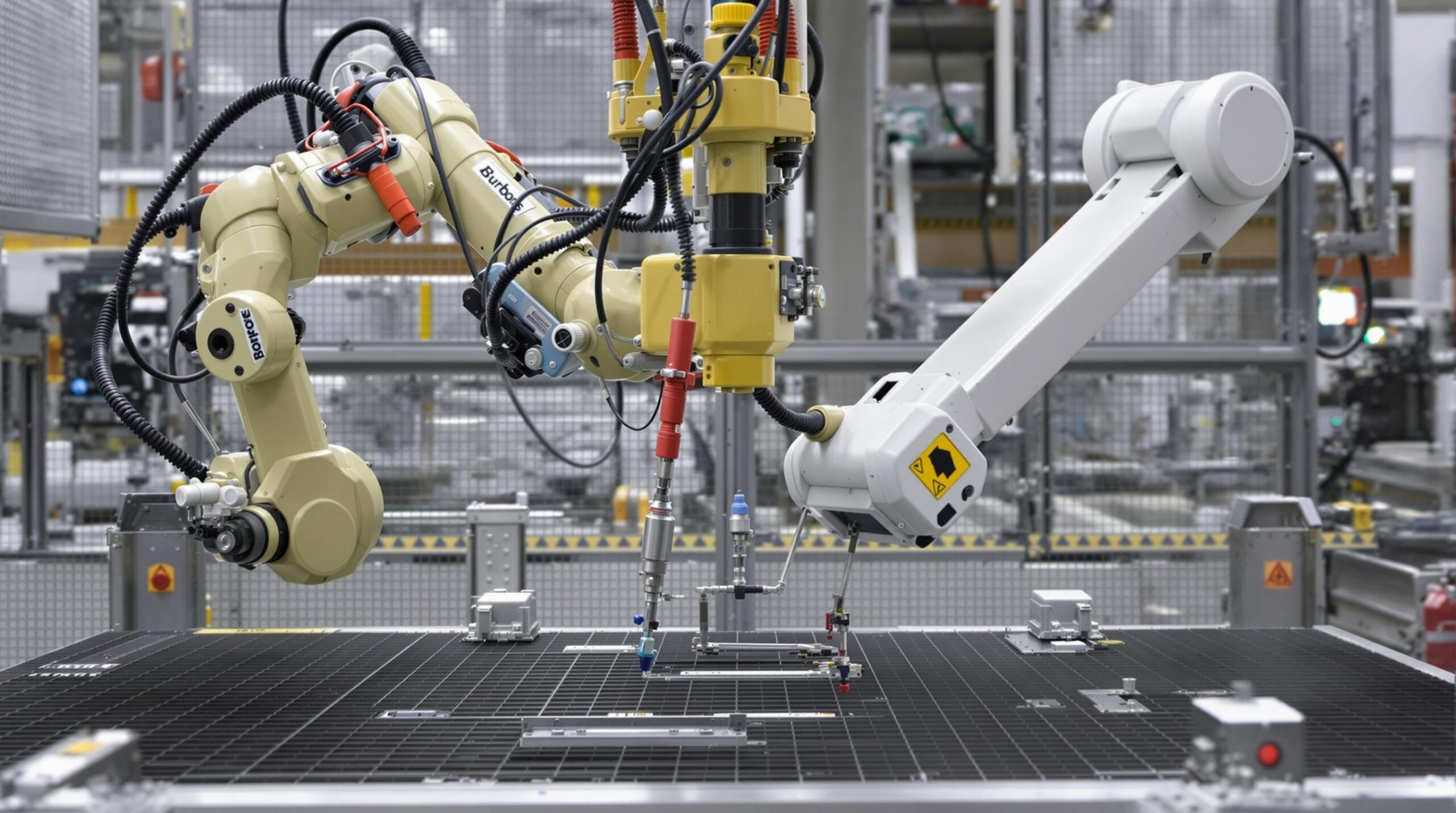

Automotive: Driving Electric Vehicle Production

The automotive industry is experiencing a transformation with 75% of manufacturers anticipating EV production growth in 2025. Mobile robots and cobots are proving essential to this transition, offering flexibility for the unique assembly challenges of electric vehicles compared to traditional combustion engines.

According to ABB Robotics, 31% of surveyed experts predict over 10% EV output growth in the immediate future. However, 65% doubt achieving full EV production by 2040, highlighting both optimism for near-term growth and skepticism about complete industry transformation.

Cobots excel in battery assembly tasks requiring extreme precision, while humanoid robots are being tested for more complex operations. The automotive sector demonstrates how robots are used to address both technical manufacturing challenges and labor shortages in a rapidly evolving industry.

Healthcare: Enhancing Patient Care and Safety

Healthcare robotics represents one of the most promising growth sectors, valued at $1.5 billion in 2022 and growing at 13.5% CAGR through 2032. Pharmacy automation robots, which sort and dispense medications with perfect accuracy, are projected to reach a $3.5 billion segment by 2032.

UV-C radiation robots play a crucial role in infection control, automatically disinfecting hospital rooms without human exposure to harmful chemicals or pathogens. Meanwhile, autonomous mobile robots (AMRs) handle supply transportation in 53% of large hospitals, reducing staff workload and enabling more time for patient care.

Regional differences are significant, with North America holding a $2 billion market share while Asia shows tremendous growth potential. These technologies address critical healthcare challenges like medication errors and hospital-acquired infections while increasing operational efficiency.

Agriculture: Cultivating Robotic Field Workers

Agricultural robotics is witnessing rapid expansion, with the market projected to grow from $14.97 million in 2023 to $35.44 million by 2032. AI-powered harvesters can identify ripe produce and pick it with minimal damage, addressing labor shortages during harvest seasons.

Drones equipped with advanced sensors and autonomous tractors enable precision spraying, reducing pesticide use by 20%. This targeted approach not only cuts costs but also provides significant environmental benefits. The economics are compelling: human labor costs approximately $35/hour versus $10/hour for robotic alternatives.

Adoption rates vary widely by region and farm size, with 45% of large North American farms utilizing automation compared to much lower rates in developing regions. IoT sensors integrated with robotics provide real-time data on soil conditions, crop health, and weather impacts, enabling data-driven farming decisions that maximize yields.

Construction & Mining: Building and Excavating with Precision

The construction robots market is set to grow from $1.37 billion in 2024 to $3.8 billion by 2030, driven by innovations in 3D printing and demolition robotics. Automated bricklaying robots reduce project timelines by 30% while addressing the growing urbanization demands—an estimated 13,000 new buildings will be needed daily by 2050.

In mining, swarm robots modeled after honeybee behavior have improved ore extraction efficiency by 40% in Australia’s Pilbara mine. Autonomous haul trucks reduce human exposure to hazardous conditions, cutting mining accident rates by 25%.

The investment considerations are substantial, with robotic mining systems costing approximately $2 million each but offering ROI within 3-5 years through increased productivity and safety benefits. These applications showcase where robots are used to address both dangerous working conditions and labor shortages in physically demanding industries.

Education & Entertainment: Robots as Teachers and Performers

The educational robot market is surging from $1.64 billion in 2025 to a projected $5.84 billion by 2030, revolutionizing how STEM subjects are taught. Regional adoption varies significantly, with Asia Pacific growing at 23.06% CAGR while North America currently holds 37% of revenue.

Humanoid robots engage students through interactive learning experiences, while specialized coding kits teach programming fundamentals. The price point matters significantly, with non-humanoid educational robots costing 40% less than their humanoid counterparts, affecting school adoption rates.

In entertainment, Disney’s animatronic robots in “Star Wars: Galaxy’s Edge” have increased visitor engagement by 50%. AI-driven robotic performers in Cirque du Soleil have reduced rehearsal time by 35% through motion-capture technology. These applications demonstrate how robotics enhances both educational outcomes and entertainment experiences through personalized interactions.

Hospitality & Retail: Enhancing Customer Service

Retail robots are transforming inventory management, with Sam’s Club reporting a 27% reduction in stockouts after deploying Inventory Scan robots. This addresses a significant portion of the $634.1 billion in annual retail losses attributed to inventory mismanagement.

In hospitality, hotel check-in robots improved customer satisfaction by 18% post-COVID, offering contactless service options. However, surveys indicate 31% of guests still prefer human staff, highlighting the need for balanced implementation. Hilton’s multilingual concierge robots demonstrate advanced customer service capabilities, particularly in international properties.

The cost-benefit analysis is compelling, with savings of approximately $500,000 per year per retail store. However, privacy concerns remain as robots collect customer data, requiring transparent policies around information gathering and use. This sector illustrates how robots are enhancing operations while complementing rather than replacing human touchpoints.

Sources

For more information about the various uses of robots across different industries, check out these resources:

International Federation of Robotics – Record of 4 Million Robots Working in Factories Worldwide

The Robot Report – ABB Robotics Survey Predicts EV Production Growth 2025