Robotic arms have revolutionized modern industry by replicating human arm functions with enhanced precision, speed, and operational capabilities. These programmable mechanical systems have transformed manufacturing processes across various sectors, enabling 24/7 operations in environments that would otherwise be hazardous or impossibly repetitive for human workers.

Key Takeaways

- The global robotic arm market is projected to grow from $36.93 billion in 2024 to $80.82 billion by 2029

- Most industrial robotic arms feature 4-6 axes of motion with precision down to ±0.1 mm

- Articulated, SCARA, and Cartesian designs represent the most common types of robotic arms in industrial settings

- Collaborative robots (cobots) are reducing setup time by 50% compared to traditional industrial automation

- AI integration in robotic systems is optimizing performance while reducing energy consumption by up to 20%

Understanding Robotic Arm Anatomy

A robot robotic arm consists of several interconnected segments (links) powered by joints and actuators that work together to perform precise movements. These mechanical marvels replicate human arm functionality but with superior repeatability and endurance. Most industrial models feature between 4-6 axes of motion, with six-axis articulated arms offering the most human-like flexibility for complex manufacturing tasks.

The fundamental components of any robotic arm include joints (either rotary or prismatic mechanisms), End-of-Arm Tooling (EOAT), and sophisticated control systems. The joints function as the “muscles” of the arm, while EOATs represent the specialized “hands” that interact directly with workpieces. These end effectors account for 15-20% of total robotic system costs but are essential for task-specific precision.

Controllers serve as the “brain” of the system, coordinating movements with remarkable precision—often achieving accuracy within ±0.1 mm. This level of precision allows industrial robotic arms to perform complex operations consistently over extended periods, far exceeding human capabilities in both speed and accuracy.

Major Types of Robotic Arms

The robotics industry has developed several specialized types of robotic arms to address different industrial needs. Each design offers unique advantages for specific applications:

Cartesian/Gantry robots operate on three linear axes (X, Y, Z), making them ideal for applications requiring movement within a rectangular workspace. These systems excel in 3D printing, CNC machining, and pick-and-place operations where linear precision is paramount.

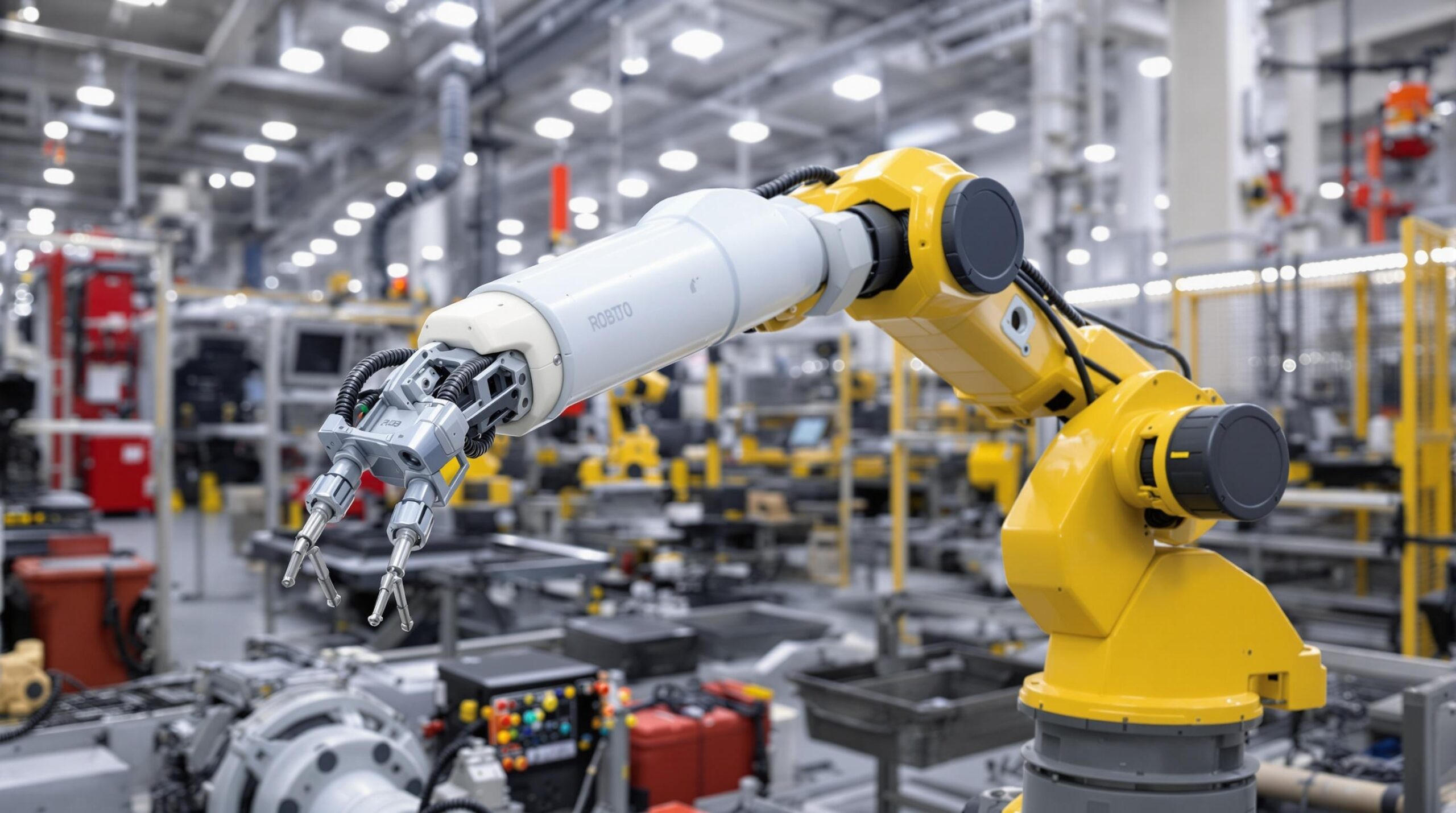

Articulated arms represent the most versatile and widely recognized industrial robotic arm configuration. With six rotating joints mimicking a human shoulder, elbow, and wrist, these arms dominate automotive assembly lines. Their flexibility allows them to perform complex tasks like welding, painting, and assembly in confined spaces.

SCARA (Selective Compliance Assembly Robot Arm) robots are optimized for horizontal movements, achieving impressive speeds of up to 10,000 cycles per hour with 0.02 mm repeatability. This makes them perfect for electronics assembly and other applications requiring rapid, precise planar movements.

Collaborative Robots (Cobots) represent the newest class of robotic arms, designed to work alongside humans without safety barriers. Featuring force-limiting sensors and intuitive programming interfaces, cobots can reduce setup time by 50% compared to traditional industrial robots.

Delta/Parallel robots use lightweight carbon-fiber arms connected to a common base, enabling them to handle over 300 items per minute in food and pharmaceutical packaging. Their parallel kinematic structure provides unmatched speed for light-payload applications.

Industrial Manufacturing Applications

The automotive industry has been at the forefront of robotics applications in manufacturing, with robotic arms performing approximately 95% of spot welding in modern car production. This automation has reduced cycle times by 30% while decreasing defect rates by 25% compared to manual methods.

Machine tending represents another critical application, where robotic arms load and unload CNC machines with 99.8% uptime, enabling true “lights-out” manufacturing. A single Fanuc M-20iB/25 arm can service multiple machines simultaneously, dramatically improving production efficiency.

Articulated six-axis arms dominate manufacturing settings due to their versatility and precision. These systems replicate human shoulder, elbow, and wrist motions, allowing them to navigate complex assembly tasks with consistent accuracy—something particularly valuable in industries with stringent quality requirements.

According to Vention.io, six-axis articulated arms account for the majority of industrial robotics deployments, thanks to their ability to perform diverse tasks within a single production line. Their human-like range of motion makes them exceptionally adaptable to changing manufacturing requirements.

The E-Commerce Revolution

The rapid growth of e-commerce has created new opportunities for robotic arm integration in fulfillment and logistics operations. Palletizing robots can now automate the handling of more than 1,500 cases per hour in warehouse environments, cutting labor costs by 70% while improving load stability and consistency.

The e-commerce sector’s 7.6% growth in 2023 has fueled demand for robotic sorting systems capable of handling diverse product types. Companies like RightHand Robotics are pioneering advanced gripper technologies specifically designed for the irregular items common in online retail.

Mobile manipulation represents an exciting development in this space, combining autonomous mobile robots (AMRs) with mounted robotic arms to create flexible assembly lines. This integration reduces reconfiguration time from weeks to mere hours, allowing warehouse operations to adapt quickly to changing business needs.

According to The Business Research Company, the combination of AI-powered robotics and e-commerce demand is driving significant market growth, with robotic arms becoming increasingly essential in modern distribution centers.

Healthcare and Specialized Applications

The surgical robotics market, valued at $7.3 billion in 2024, relies on sophisticated seven-axis arms like Medtronic’s Hugo RAS for minimally invasive procedures. These highly specialized robotic systems have demonstrated the ability to reduce patient recovery time by 40% compared to traditional surgical approaches.

Advanced research institutions like MIT have developed innovative applications such as RoCycle, which detects material composition with 85% accuracy using tactile sensors. This technology enables automated waste sorting and separation, addressing critical environmental challenges through robotic automation.

These specialized applications demonstrate how robotic arm technology extends far beyond traditional manufacturing. The precision and adaptability of modern robotic systems make them valuable tools in fields ranging from medical procedures to environmental management.

The versatility of robotic arm systems has allowed them to find applications in nearly every industry, with each sector adapting the technology to address its unique challenges and opportunities. This cross-industry adoption continues to drive innovation in both hardware and control systems.

Technological Advancements

AI integration represents one of the most significant advancements in modern robotic arms. Machine learning algorithms can now optimize path planning and movement patterns, reducing energy consumption by up to 20% while improving accuracy. These intelligent control systems enable robots to adapt to variations in their environment and work processes.

Soft robotics technologies have revolutionized gripper design, improving the handling of delicate or irregular objects. Advanced vision systems now enable real-time adjustments and quality control, allowing robotic arms to perform tasks that were previously considered too complex for automation.

Major vendors in the industrial segment include ABB, KUKA, and Yaskawa, with each company offering specialized solutions for different applications. Despite a 30% reduction in costs since 2020, high initial investments ranging from $50,000 to $500,000 remain a significant barrier for many smaller manufacturers.

The integration of machine learning, improved sensors, and more sophisticated control systems is transforming industrial robotics, making these systems more adaptable and easier to implement across a broader range of applications.

Future Trends and Challenges

Swarm robotics represents an emerging approach where coordinated fleets of simpler arms work together on complex tasks. Tesla’s “Optimus” humanoid project exemplifies this trend, aiming to create systems where multiple robots can collaborate effectively in manufacturing environments.

Self-healing systems like DLR’s variable-stiffness actuators can detect joint wear and adjust accordingly, potentially extending service life by 200%. This development addresses one of the key maintenance challenges in industrial robotics.

Experimental models using quantum sensors for nanoscale positioning hint at future applications in semiconductor fabrication and advanced materials processing. These systems promise unprecedented precision for specialized manufacturing tasks.

Despite these exciting developments, significant challenges remain. High initial costs continue to limit adoption among small and medium enterprises. Integration with existing factory automation systems presents technical hurdles, and the ongoing need for skilled technicians to program and maintain these systems creates workforce development challenges.

As robotic arm technology continues to advance, the balance between cost, capability, and ease of implementation will determine how quickly these systems spread through global manufacturing and service industries.

Sources

RS Components – A Complete Guide to Robotic Arms

Intel – Industrial Robotic Arm Overview

Vention.io – Robotic Arms in Manufacturing: How and Where They’re Used

Telefónica – What Are the Most Commonly Used Robotic Arms in Industry?

OpenPR – Robotic Arm Market Forecast 2025–2034

Standard Bots – How Do Robotic Arms Work? A Comprehensive Guide